| Material | Plastic, Bamboo, Wood |

| Feature | Waterproof, Fire Retardant, Moisture-Proof, easily clean, Eco-Friendly |

| After-sale Service | Online technical support |

| Place of Origin | Shandong,China |

| Warranty | More than 5 years |

| Installation | easy installation,GLUE |

| Material | 40% PVC, 55% CaCO3, Carbon +Wood Powder |

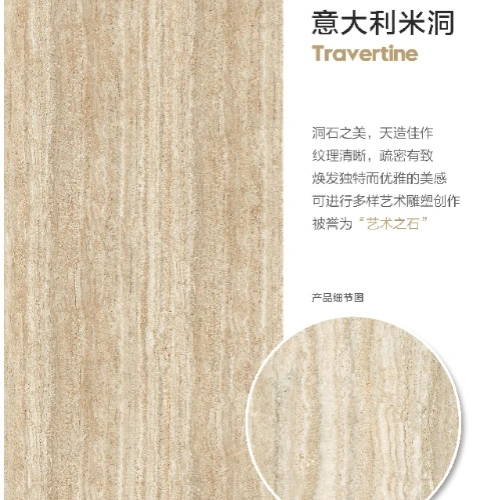

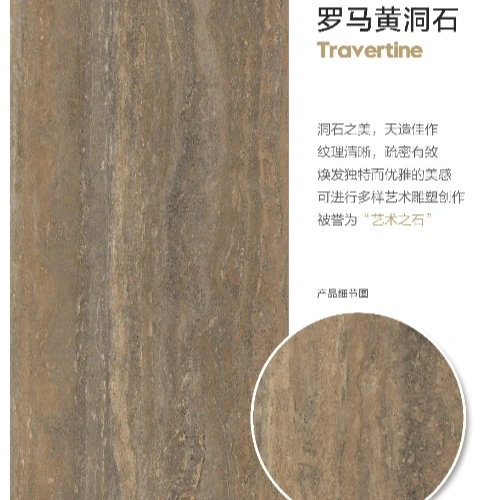

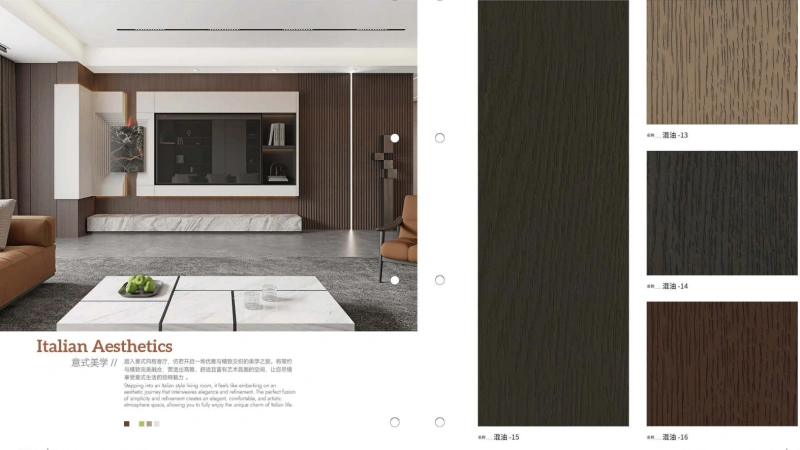

| Color | Marbled, Wood Grain, Mirror, Ripples, Fabric, Customize |

| Length | 2.4-6M,Customized |

| Width | 1220MM/1150MM, Customized |

| Thickness | 5/8MM, Customized |

| Weight | 550KG/M3 ~ 880KG/M3 |

| Advantage | Fireproof, Waterproof, ECO-Friendly |

| Usage | Interior Decoration Wall Panel / Ceiling |

| Certification | CE / ISO9001 |

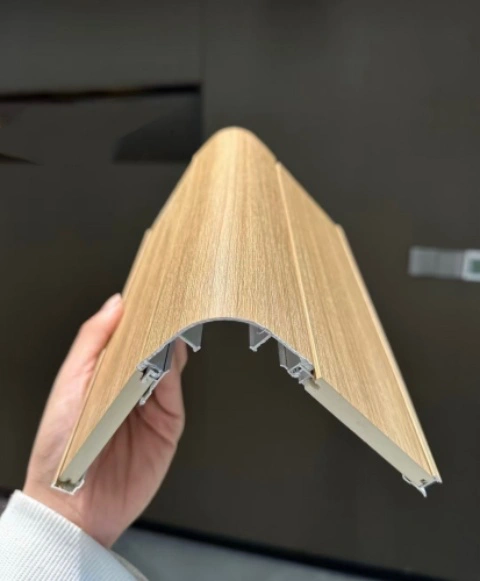

Manufacturing Process: Extrusion Technology

The production of virgin bamboo panels utilizes state-of-the-art extrusion technology, setting it apart from traditional bamboo strip bonding methods:

1. Material Preparation: Bamboo wood powder is sourced from sustainably managed forests, with each ton of powder derived from approximately 200 mature bamboo culms. The powder is then mixed with calcium carbonate powder (particle size 300-500 mesh) and PVC resin in strictly controlled proportions.

1. Extrusion Molding: The mixture is fed into an extruder where it is heated to 180-200°C and subjected to a pressure of 15-20 MPa. This process melts the PVC and binds the bamboo wood powder and calcium carbonate, forming a continuous substrate sheet with a thickness ranging from 3mm to 20mm. The extrusion line operates at a speed of 5-8 meters per minute, ensuring high-volume production.

1. Surface Treatment: After extrusion, the substrate undergoes a cooling process to stabilize its dimensions. It is then subjected to a heat lamination step, where various decorative films (including wood grain, stone texture, and solid colors) are bonded to the surface at a temperature of 120-150°C and pressure of 0.5-0.8 MPa. This thermal bonding ensures a strong adhesion with a peel strength of over 3N/cm, guaranteeing long-term durability.

This manufacturing process results in panels with exceptional properties: a density of 1.1-1.3 g/cm³, tensile strength of 30-40 MPa, and impact strength of 20-25 kJ/m². These metrics, validated by the China Building Materials Testing Center, demonstrate the panel's superior performance compared to traditional wood-based panels.

Key Advantages Backed by Data

1. Environmental Benefits: The use of bamboo wood powder reduces reliance on hardwoods, with each ton of virgin bamboo panels saving approximately 0.8 cubic meters of timber. The extrusion process achieves a material utilization rate of over 95%, minimizing waste compared to traditional cutting methods which typically have a 70-75% utilization rate.

1. Durability: Laboratory tests show that virgin bamboo panels have a water absorption rate of less than 2% after 24 hours of immersion, significantly lower than MDF's 10-12% and particleboard's 8-10%. This makes them highly resistant to moisture, ideal for humid environments.

1. Cost-Effectiveness: The production cost of virgin bamboo panels is 15-20% lower than that of solid bamboo panels, thanks to the efficient extrusion process and optimized material blend. This cost advantage is passed on to customers without compromising quality.

1. Versatility: The panels can be produced in lengths up to 6 meters and widths up to 1.2 meters, with a thickness tolerance of ±0.1mm, ensuring precision for various applications. The heat-bonded decorative films offer over 100 different patterns, from natural wood grains to modern abstract designs.

Main Application Scenarios

1. Residential Interior Design

1. Wall Cladding: Virgin bamboo panels are perfect for residential wall decoration. A case study in a high-rise apartment complex in Hangzhou showed that using these panels for living room walls reduced installation time by 30% compared to ceramic tiles. The panels' thermal conductivity of 0.15-0.2 W/(m·K) provides better insulation than gypsum boards (0.25-0.3 W/(m·K)), contributing to energy savings of 8-10% for indoor heating and cooling.

1. Commercial Spaces

1. Retail Stores: In a chain of fashion boutiques across Shanghai, virgin bamboo panels were used for display shelves and counter tops. The panels' high impact resistance (20-25 kJ/m²) withstood daily wear and tear, reducing maintenance costs by 25% compared to previous wooden fixtures. The wide range of decorative films allowed each store to maintain a consistent brand image while having unique design elements.

1. Office Interiors: A tech company's headquarters in Shenzhen utilized virgin bamboo panels for partition walls and workstation surfaces. The panels' fire resistance rating of B1 (flame-retardant) met strict safety standards, while their sound absorption coefficient of 0.2-0.3 helped reduce noise levels in open-plan offices by 15-20%.

Our Services

1. OEM Services: We offer comprehensive OEM solutions, producing panels under your brand name with customized specifications. Our production lines can handle orders as small as 500 m², with a lead time of 7-10 days for standard products and 15-20 days for custom formulations.

1. Customization Options: Beyond standard sizes, we provide tailored solutions including:

1. Custom thickness from 2mm to 30mm

1. Specialized decorative films (anti-bacterial, anti-UV, fire-retardant)

1. Pre-cut panels with precision CNC machining (tolerance ±0.5mm)

1. Custom color matching with a minimum order quantity of 1000 m²

1. Wholesale Distribution: We offer competitive wholesale pricing with tiered discounts: 5% off for orders over 5000 m², 8% off for over 10,000 m², and 12% off for over 20,000 m². Our DAILY production capacity of 10000PCS ensures timely delivery even for large orders.

Global Reach and Support

TOPSHINE serves customers across 30+ countries, with established logistics partnerships ensuring efficient delivery to major ports worldwide. We provide:

· FOB, CIF, EXW shipping options

· Free samples within 3 working days

· Technical support with detailed installation guides in 10 languages

· 5-year product warranty backed by international insurance

Our commitment to quality is demonstrated by our ISO 9001:2015 certification and compliance with international standards including ASTM, EN, and JIS. Each batch of panels undergoes 12 quality checks, from raw material inspection to final packaging, ensuring consistent performance.

In conclusion, virgin bamboo panels represent the future of sustainable building materials, combining eco-friendliness, durability, and affordability. TOPSHINE stands ready to meet the global demand with our advanced manufacturing capabilities, customizable solutions, and dedicated customer service. Whether you're a furniture manufacturer, interior designer, or construction company, our virgin bamboo panels offer a versatile and cost-effective solution for your projects. Contact us today to discuss your requirements and discover how we can support your business growth.