What Is SPC Flooring

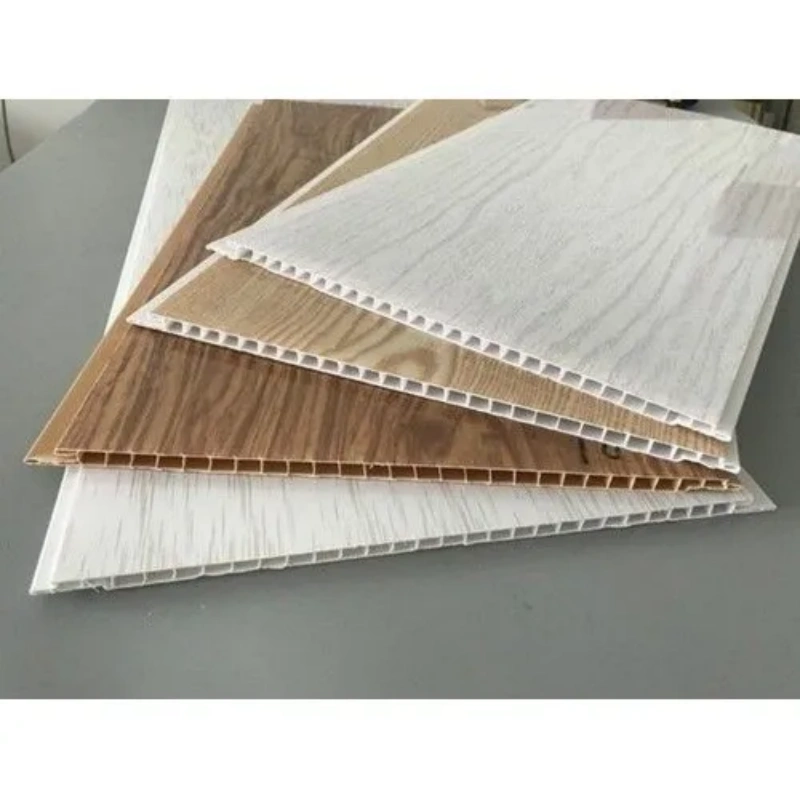

SPC flooring, a cutting-edge vinyl flooring solution, is engineered from stone polymer composite materials, ensuring exceptional durability and resistance to both moisture and wear. This innovative flooring option is highly favored in both residential and commercial settings due to its ease of installation and low maintenance requirements.

Our SPC flooring stands out for its superior quality, utilizing 100% virgin material to guarantee unparalleled durability and long-lasting aesthetic appeal. Crafted to meet stringent heavy-duty performance standards, our flooring not only delivers enduring beauty but also enduring functionality.

Why hesitate? Contact us today to request your complimentary samples and discover firsthand why our SPC flooring is a preferred choice among discerning customers.

SPC flooring specification | |

Color | Several hundreds of color available |

Thickness | 5mm SPC flooring |

Size: | 1200 x 184 mm, 915 x 150 mm, 930x310mm, etc. |

Top wearlayer | 0.3mm, 0.5mm |

Special treatment | Painted V-groove, soundproof IXPE |

Surface treatment | Deep embossed, EIR, Crystal,Wood grain, Flat,Stone |

Material | 100% virgin material |

Click system | Unilin click system |

Installation Method | Floating |

SPC flooring loading | |

Pcs/ctn | 8 |

Weight(KG)/ctn | 18.5 |

Ctns/pallet | 60 |

Plt/20’FCL | 20 |

Sqm/20’FCL | 2173 |

Weight(KG)/G.W | 22300 |

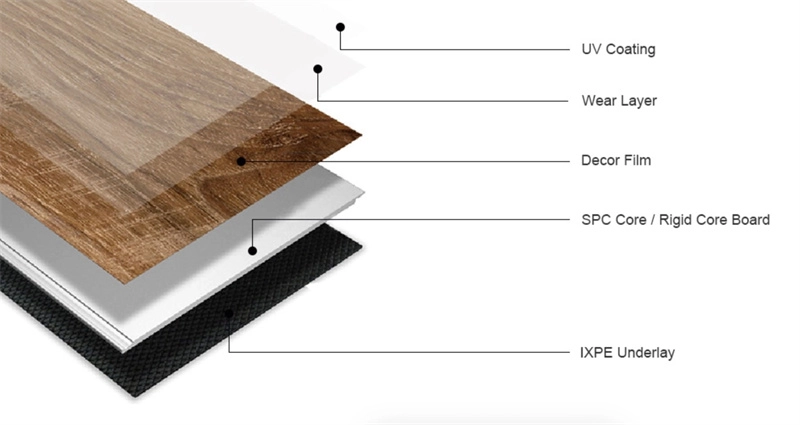

1. UV Coating

It enhances the clarity of the decoration film and resists fading.

2. Wear Layer

Scratch Resistance. For durability over 20 years. Widely used for residential areas, shopping malls, etc.

3. Decorative Film

Modern design based on the most popular models on the market.

4. SPC Rigid Core

It is made of superfine stone plastic composite material.

5. Underlayment (Optional)

It uses IXPE or EVA, can enhance the floor’s grip, fits existing surfaces, and reduces noise.

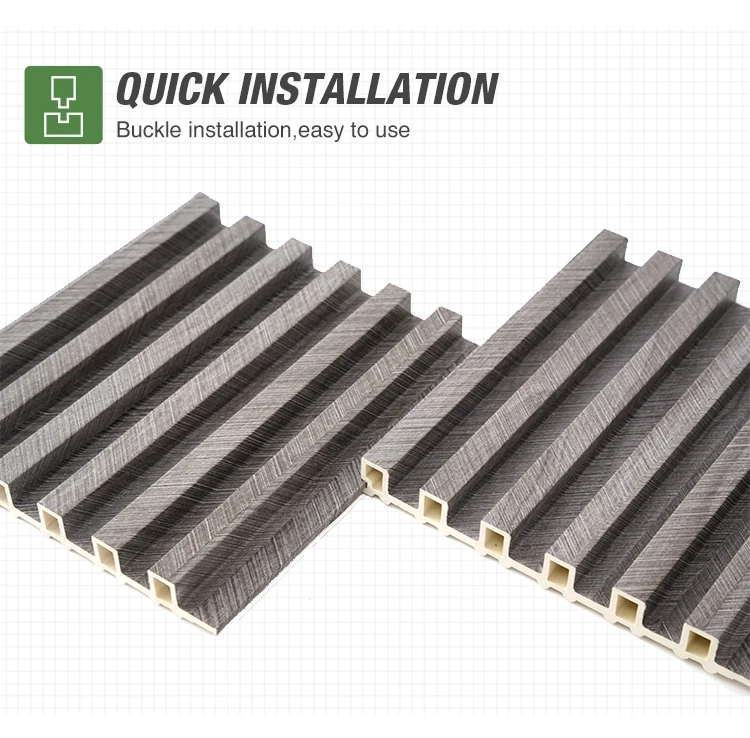

6. Click-Lock Installation System

Easy installation and making the floor sturdy and waterproof.

Characteristics | Test | SPC |

Dimension | ISO24341 | |

Thickness | ISO24346 | 5MM |

Wear Layer Thickness | ISO24340 | 0.2MM,0.3MM,0.4MM |

Weight | EN430 | 9.3KG/M2 |

Fire Resistance | En1350/ISO9239-1 | Clsss Bf1S1(B1) |

Dimensinal Stability | ISO23999 | ≤0.12% |

Color Fastness | ISO105-B02:1994 | ≥Grade6 |

Slip Resisitance | AS4586/DIN51130 | R10 |

Formaldehyde Emission | EN717-1 | E0 |

Curving | ISO23999 | ≤1.2MM |

Peel Resistance | ISO24345 | ≥75N/5CM |

Click Force | ISO24334 | ≥120N/5CM |

Anti-scratches | -- | ≥2500G |

Acoustic Performance | EN ISO 717-2 | Lw=10db |

Cigarette burn resistance | EN438-2 | Class 3 |

Castor Chair | ISO4918 | After 25000 cycles,no delamination occur.No disturbance to the surface other than a slight change in appearance |

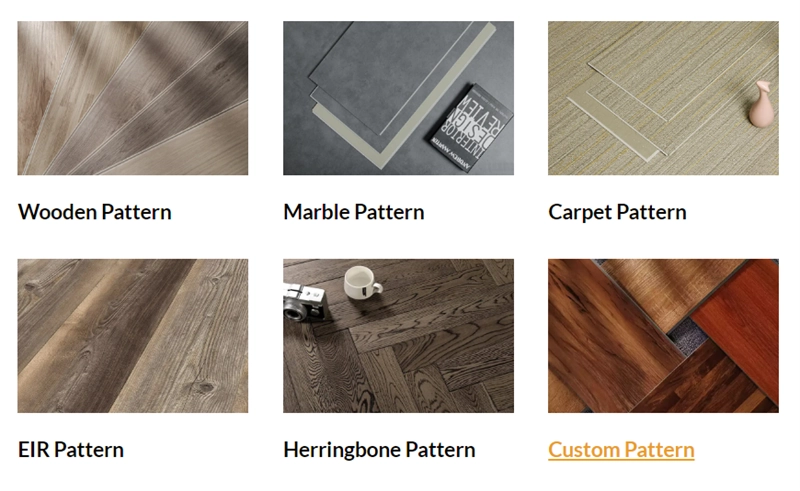

Our Patterns

Choose The Suitable Patterns For Your Floor

SPC flooring comes in various colors and patterns, including wooden/marble/carpet patterns, so it is easy to find a style that fits your business and projects.

Wooden Pattern+Marble Pattern+ Carpet Pattern+EIR Pattern+ Herringbone Pattern+Custom Pattern

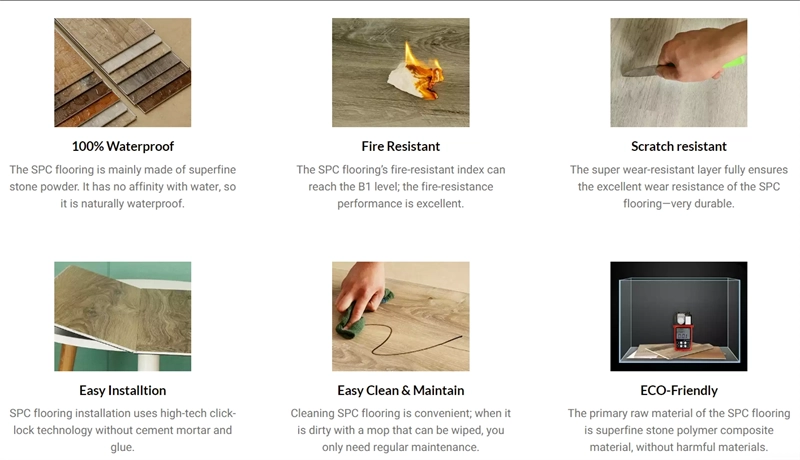

Feartures & Benefits

SPC Flooring Advantages

SPC flooring comes in various colors and patterns, including wooden/marble/carpet patterns, so it is easy to find a style that fits your business and projects.

100% Waterproof+Fire resistance +Easy Installation+Easy Clean and Maintain+Scratch resistance+ECO-Friendly

Why Choose Us

Our Experience in Vinyl Flooring Manufacturingdates back to 15 years ago

We are passionate about providing our customers with high-quality vinyl flooring , We use the latest technology and equipment to create various colors and styles to meet customers’ needs.

*Best Quality Standards

*100% Satisfaction Guarantee

*Quality Control System

*Commitment to Customers

*Highly Professional Team

*Best virgin Materials

How is SPC flooring made?

SPC (Stone Plastic Composite) flooring is a type of rigid core vinyl flooring that is engineered for stability and durability. It's made from natural limestone powder, polyvinyl chloride, and stabilizers. Here's how SPC flooring is made:

Raw Materials: The primary components of SPC flooring are natural limestone powder, polyvinyl chloride (PVC) resin, stabilizers, and pigments for color. These materials are carefully measured and mixed according to a specific formula.

Mixing: The limestone powder and PVC resin are mixed together thoroughly to form a homogenous mixture. This mixture provides the flooring with its rigidity and stability.

Extrusion: The mixed material is then fed into an extruder, which shapes the flooring planks. The extruder applies heat and pressure to the mixture, forming it into the desired plank shape. During this process, decorative patterns and textures can be embossed onto the surface to mimic the look and feel of natural materials like wood or stone.

Calendering: After extrusion, the planks go through a calendering process where they are heated and pressed between rollers. This step further enhances the plank's stability and thickness uniformity.

UV Coating: A UV-resistant coating is applied to the surface of the SPC planks. This coating protects the flooring from fading and wear caused by sunlight and daily use.

Cutting: The continuous sheets of SPC flooring are cut into individual planks of various sizes. Precise cutting ensures that the planks have straight edges and consistent dimensions.

Quality Control: The finished SPC planks undergo quality control checks to ensure they meet the desired standards in terms of dimensions, appearance, and overall quality.

Packaging: Once the quality control checks are complete, the SPC flooring planks are packaged and prepared for shipping.

The Comprehensive Process of Packing and Shipping SPC Flooring

SPC flooring, as a popular flooring material, requires a careful packing and shipping process to ensure that the product remains intact during transportation. This article will provide you with a detailed overview of the entire process of packing and shipping SPC flooring to enhance your understanding of it.

Step One: Selecting Appropriate Packaging Materials

Before packing SPC flooring, you need to prepare suitable packaging materials, including but not limited to:

High-Strength Cardboard Boxes: Used to neatly and orderly package SPC flooring, providing protection.

Foam Padding or Foam Sheets: Used to cover the inside of the cardboard boxes or the surface of the flooring to add a protective cushion.

Tape and Packing Straps: Used to seal the cardboard boxes securely.

Corner Protectors: Used to protect the corners of the cardboard boxes to prevent them from getting damaged due to impacts during transportation.

Step Two: Sorting and Packaging the Flooring

Clean the Flooring Surface: Before packaging, ensure that the surface of the SPC flooring is clean and free from dust or debris.

Stack the Flooring: Neatly stack the SPC flooring according to specifications and dimensions.

Add Protective Layers: Insert foam padding or foam sheets on the surface of the flooring and inside the cardboard boxes to provide additional protection.

Boxing: Place the neatly organized SPC flooring batches into high-strength cardboard boxes, ensuring there are no gaps inside the boxes.

Step Three: Sealing and Labeling

Seal the Boxes: Seal the top and bottom of the cardboard boxes using tape and packing straps to ensure the boxes are securely closed.

Labeling: Affix appropriate labels on the boxes, indicating the product name, quantity, specifications, and other relevant information. This helps with tracking and identification during shipping.

Step Four: Stacking and Loading

Stacking: The packaged SPC flooring should be stacked neatly in the warehouse or shipping point, avoiding direct contact with moisture, sunlight, or other environmental factors.

Loading: Prior to shipping, load the flooring onto transportation vehicles. During the loading process, ensure that the flooring is well-supported and balanced to prevent squeezing and deformation.

Step Five: Transportation and Delivery

Select Suitable Transportation Mode: Depending on the transportation distance and quantity, choose an appropriate mode of transportation, including land transport, sea transport, or air transport.

Tracking and Monitoring: Throughout the transportation process, track and monitor the condition of the SPC flooring to ensure that the product arrives safely at its destination.

Receiving and Inspection: Upon receiving the SPC flooring, customers should promptly inspect the goods to ensure that they are in good condition.

Through this detailed process, we aim to provide you with knowledge about the packing and shipping of SPC flooring, ensuring that the product remains in optimal condition during transportation and offering you high-quality products and services. If you have any questions or require further information, please feel free to contact us.

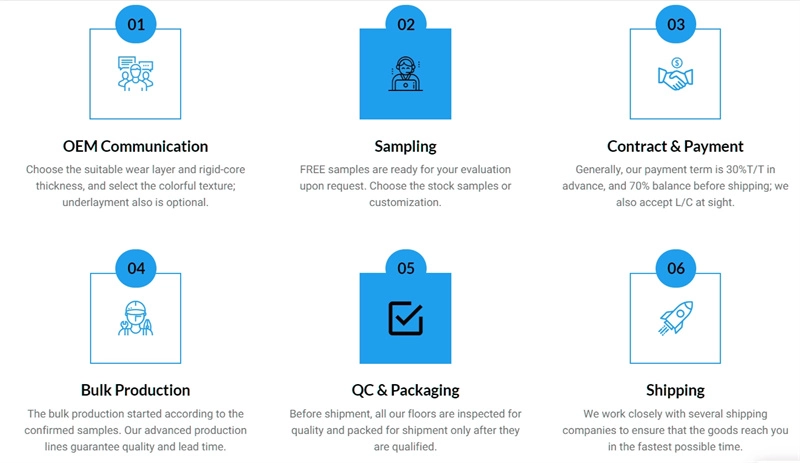

Work With Us

Our Working Proccess

SPC vinyl flooring from China offers unmatched durability, water resistance, and a wide range of colors, making it a popular choice for residential and commercial spaces worldwide. Crafted from a blend of stone and plastic composite materials, it can withstand heavy foot traffic and is ideal for busy areas. Its waterproof nature makes it perfect for moisture-prone spaces like bathrooms and kitchens. Homeowners and designers can choose from a vast array of colors and designs, including wood grain and stone textures, providing a natural look without the associated maintenance and cost. China is a leading producer of SPC vinyl flooring, benefitting from economies of scale and efficient production processes, leading to cost-effective solutions. This ensures high-quality products at competitive prices, making it a preferred option for consumers.

305.webp)