ABOUT ENGINEERED HARDWOOD FLOORING

l Top quality solid hardwood backed by an engineered wood core, makes it very durable

l A lower price When compared to traditional hardwood, engineered wood

l Optional hand scraped, wire brushed, distressed finishes

l Can be installed over concrete subfloors, in basements (below grade), and some over radiant heat

l Can be sanded and refinished, but only once or twice depending on the floor

Engineered Wood Floor Technical Specification | |||

Size(mm) | Species | Finish | Surface |

12/3x150x600 14/3x190x1900 15/4x220x2200 or as request | European Oak | Brushed & UV Oiled or UV Lacquered

| Smoked,Stained color |

Certificates | CE,FSC,CARB,ISO | ||

Packing

Packing and shipping engineered wood flooring requires careful handling to ensure the products reach their destination in good condition. Here are the stepsto pack and ship engineered wood flooring:

1. Prepare the Engineered Wood Planks:

Ensure the planks are clean and dry.If applicable, bundle the planks in sets based on size and type.

2. Wrap Individual Planks:

Wrap each plank with bubble wrap to protect against scratches and minor impacts.

3. Prepare the Boxes:

Line the bottom of the cardboard boxes with packing paper for extra cushioning.Place wrapped planks inside the boxes, arranging them carefully to maximize space utilization.

4. Seal the Boxes Securely:

Seal the boxes with packing tape, ensuring they are securely closed. Reinforce the bottom and edges.

5. Label the Boxes:

Clearly label each box with the destination address, contact information, and any special handling instructions.Use fragile stickers if applicable.

6. Palletize the Boxes:

If you have multiple boxes, stack them on pallets, securing them with stretch wrap.Ensure the pallets are stable and not overpacked to prevent damage during handling.

7. Choose a Reliable Shipping Carrier:

Select a reputable shipping company experienced in handling fragile items. Consider factors like shipping time, cost, and insurance options.

8. Arrange for Pickup or Drop-Off

A comprehensive step-by-step guide on how to install engineered hardwood flooring.

1. Gather the Necessary Tools and Materials:

Solid wood engineered hardwood flooring planks

Underlayment material (if required)

Moisture barrier (if necessary)

Adhesive or nails (depending on the installation method)

Hammer, nail gun, or adhesive applicator

Spacers

Tape measure

Saw (circular or miter saw)

Chalk line

Tapping block and pull bar

Safety gear (gloves, safety glasses, ear protection)

2. Prepare the Subfloor:

Ensure the subfloor is clean, dry, and level. Remove any existing flooring, nails, or debris.

Install a moisture barrier if the subfloor is concrete.

Lay down underlayment material to provide cushioning and reduce noise if necessary.

3. Acclimate the Flooring:

Bring the engineered hardwood planks into the room where they will be installed and let them acclimate for at least 48 hours. This helps the wood adjust to the room’s humidity and temperature.

4. Plan the Layout:

Plan the layout, considering the best orientation of the planks for the room’s dimensions. Use spacers to create expansion gaps along the walls.

5. Start Installation:

Begin in a corner of the room. Lay the first plank with the tongue side facing the wall, ensuring it is parallel to the longest wall.

Install the second plank by inserting its tongue into the groove of the first plank at a slight angle. Press down to engage the joint.

Continue installing planks, using a tapping block and pull bar to snugly fit the planks together. Stagger the end joints for a natural appearance.

6. Cut and Fit Planks:

Measure and cut planks using a saw to fit around doorways, vents, or other obstacles. Remember to allow for expansion gaps.

7. Complete the Installation:

Continue installing planks row by row, ensuring each row is straight and tightly connected.

When nearing the final row, measure and cut the planks to fit. Use a pry bar or pull bar to snugly fit the last row into place.

8. Finishing Touches:

Install baseboards or quarter-round molding to cover the expansion gaps along the walls. Nail or glue the molding to the base of the walls, not the flooring.

Clean the installed floor thoroughly to remove any adhesive residue or dust.

9. Maintenance and Care:

Provide information to the homeowner about proper maintenance and care, including cleaning methods and avoiding excessive moisture exposure.

By following these steps, you can achieve a professional and durable installation of solid wood engineered hardwood flooring, enhancing the beauty and value of any space.

A comprehensive guide on how to effectively care for and maintain your engineered hardwood flooring.

1. Regular Cleaning:

Sweep or vacuum: Use a soft-bristle broom or a vacuum cleaner with a hardwood floor attachment to remove dust and debris daily. This prevents scratches caused by abrasive particles.

Damp Mopping: Occasionally, use a damp (not wet) mop with a pH-neutral hardwood floor cleaner. Avoid excess water as it can damage the wood. Wipe up spills immediately to prevent stains and warping.

2. Preventive Measures:

Use Rugs and Mats: Place rugs or mats at entrances and high-traffic areas to trap dirt and prevent it from scratching the floor. Also, use felt pads under furniture legs to avoid scratches and dents.

Control Humidity: Wood can expand or contract with changes in humidity. Use a humidifier in dry seasons and a dehumidifier in humid weather to maintain stable humidity levels.

3. Avoid Damage:

High Heels and Pets: Discourage walking on the floors with high heels, and keep your pets’ nails trimmed to prevent scratches.

Furniture and Heavy Items: Lift furniture and heavy items when moving them instead of dragging them across the floor.

4. Refinishing and Repair:

Regular Inspection: Periodically inspect the floor for signs of wear, scratches, or discoloration. Promptly address any issues to prevent further damage.

Refinishing: Solid wood engineered hardwood floors can be refinished a limited number of times. Consult a professional to refinish the floor when needed, restoring its original beauty.

5. Professional Maintenance:

Professional Cleaning: Schedule professional deep cleaning periodically to remove ingrained dirt and rejuvenate the wood’s natural shine.

Sealing and Polishing: If your floor has a protective sealant, periodically check for wear and reapply the sealant if necessary. Avoid wax-based polishes, as they can make refinishing more challenging.

In conclusion, maintaining solid wood engineered hardwood flooring involves a combination of regular cleaning, preventive measures, prompt repairs, and occasional professional maintenance. By following these guidelines, you can ensure your flooring retains its beauty and durability for years to come.

Engineered hardwood flooring enhances the elegance of your home with its luxurious appearance and inviting warmth. Crafted from authentic wood, our flooring options feature a variety of European Oak wood species, stain colors, plank widths, and finishes. This versatile flooring choice is not only aesthetically pleasing but also highly durable, making it suitable for installation throughout your home, including basements and over concrete slab subfloors.

Engineered hardwood floors provide the same timeless appeal and tactile satisfaction as solid wood floors. However, they offer superior durability and cost-effectiveness. Choose our engineered hardwood flooring to bring a touch of sophistication and lasting beauty to your living spaces.

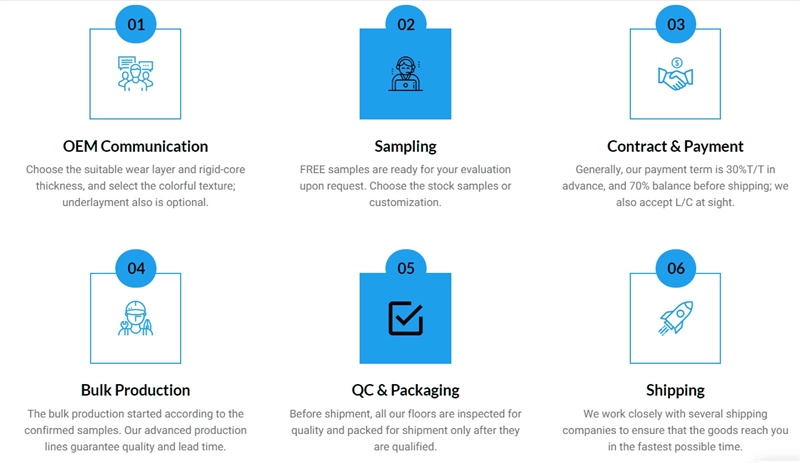

Work With Us

Our Working Proccess

305.webp)