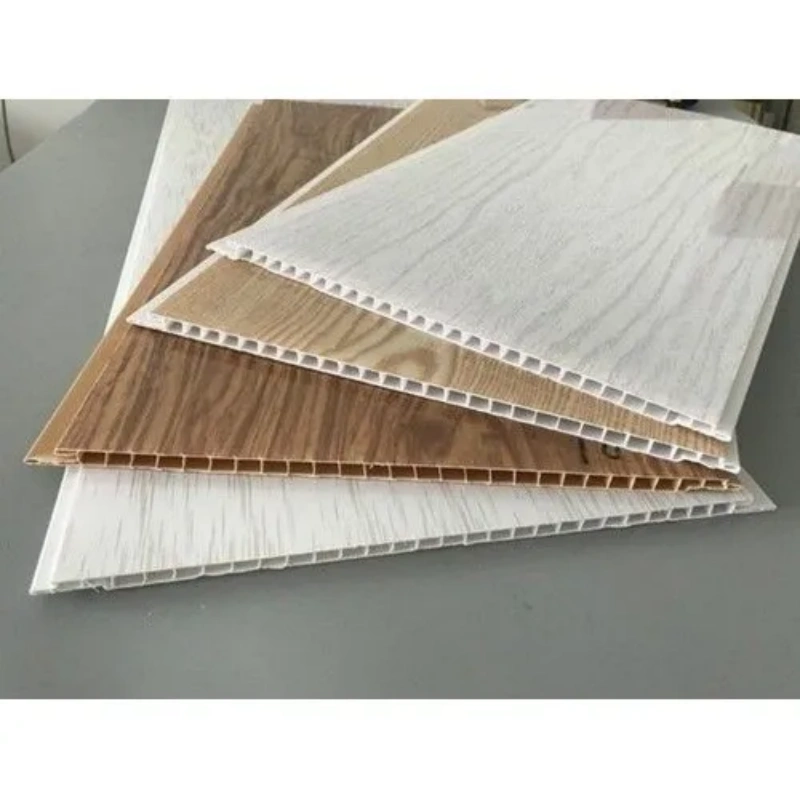

Specification | Options |

Color | Hundreds of colors available |

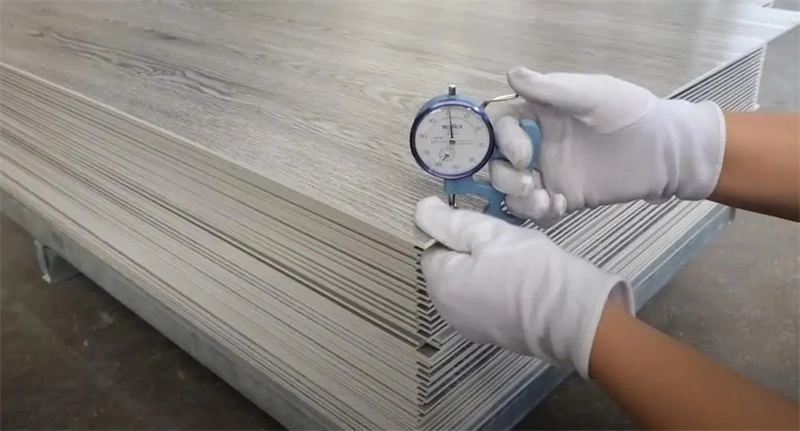

Thickness | 4mm, 4.5mm,5mm, 6mm |

Size | 1220x184mm, 914x150mm, or per request |

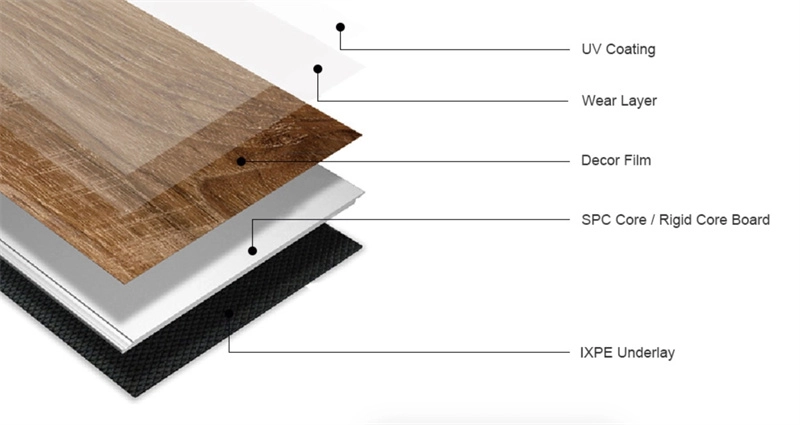

Wear Layer | 0.2mm, 0.3mm, 0.5mm |

Surface Finish | EIR, Crystal, Wood Grain, Deep Emboss, Flat, Stone |

Material | 100% virgin materials |

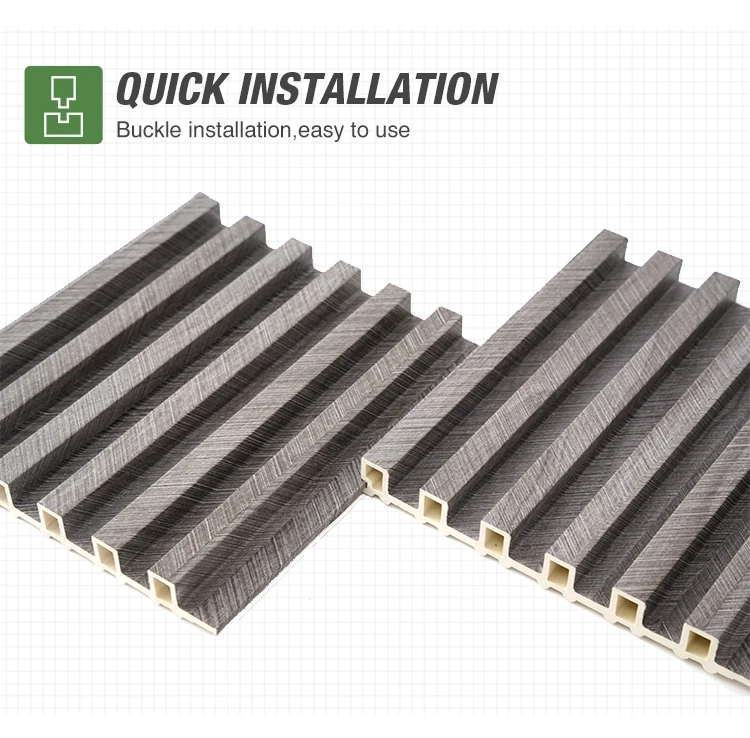

Installation Method | Locking System |

The Comprehensive Process of Packing and Shipping SPC Flooring

SPC flooring, as a popular flooring material, requires a careful packing and shipping process to ensure that the product remains intact during transportation. This article will provide you with a detailed overview of the entire process of packing and shipping SPC flooring to enhance your understanding of it.

Step One: Selecting Appropriate Packaging Materials

Before packing SPC flooring, you need to prepare suitable packaging materials, including but not limited to:

High-Strength Cardboard Boxes: Used to neatly and orderly package SPC flooring, providing protection.

Foam Padding or Foam Sheets: Used to cover the inside of the cardboard boxes or the surface of the flooring to add a protective cushion.

Tape and Packing Straps: Used to seal the cardboard boxes securely.

Corner Protectors: Used to protect the corners of the cardboard boxes to prevent them from getting damaged due to impacts during transportation.

Step Two: Sorting and Packaging the Flooring

Clean the Flooring Surface: Before packaging, ensure that the surface of the SPC flooring is clean and free from dust or debris.

Stack the Flooring: Neatly stack the SPC flooring according to specifications and dimensions.

Add Protective Layers: Insert foam padding or foam sheets on the surface of the flooring and inside the cardboard boxes to provide additional protection.

Boxing: Place the neatly organized SPC flooring batches into high-strength cardboard boxes, ensuring there are no gaps inside the boxes.

Step Three: Sealing and Labeling

Seal the Boxes: Seal the top and bottom of the cardboard boxes using tape and packing straps to ensure the boxes are securely closed.

Labeling: Affix appropriate labels on the boxes, indicating the product name, quantity, specifications, and other relevant information. This helps with tracking and identification during shipping.

Step Four: Stacking and Loading

Stacking: The packaged SPC flooring should be stacked neatly in the warehouse or shipping point, avoiding direct contact with moisture, sunlight, or other environmental factors.

Loading: Prior to shipping, load the flooring onto transportation vehicles. During the loading process, ensure that the flooring is well-supported and balanced to prevent squeezing and deformation.

Step Five: Transportation and Delivery

Select Suitable Transportation Mode: Depending on the transportation distance and quantity, choose an appropriate mode of transportation, including land transport, sea transport, or air transport.

Tracking and Monitoring: Throughout the transportation process, track and monitor the condition of the SPC flooring to ensure that the product arrives safely at its destination.

Receiving and Inspection: Upon receiving the SPC flooring, customers should promptly inspect the goods to ensure that they are in good condition.

Through this detailed process, we aim to provide you with knowledge about the packing and shipping of SPC flooring, ensuring that the product remains in optimal condition during transportation and offering you high-quality products and services. If you have any questions or require further information, please feel free to contact us.

SPC Vinyl Flooring Installation Guide: Step-by-Step

Step 1: Preparation

Before you start the installation, make sure you've completed the following preparations:

Check the Subfloor: Ensure that the subfloor is level, dry, and clean. If there are any uneven spots, they need to be repaired. The quality of your floor installation depends on the flatness of the subfloor.

Gather Materials and Tools: Ensure you have the following tools and materials: SPC flooring, underlayment, saw, measuring tools, pencil, cutting tools, adhesive, safety belt, safety goggles, etc.

Measure and Plan: Before installing, measure the dimensions of the room and calculate the required amount of flooring. Plan the direction of the flooring installation, typically parallel to the longer side of the room.

Step 2: Lay the Underlayment

Underlayment provides additional sound insulation and protects the flooring. Lay the underlayment on the dry subfloor, ensuring that the edges of the underlayment are tightly connected and secure them together with adhesive or tape. The direction of the underlayment should match the direction of the flooring installation.

Step 3: Install SPC Flooring

Prepare the First Plank: Apply an appropriate flooring adhesive to the first SPC plank and gently press it onto the underlayment. Ensure that the long edge of the plank aligns with the room's walls.

Install the Second Plank: Lock the long edge of the second plank into the long edge of the first plank. SPC flooring typically features a click-lock installation system, so you simply need to press down until you hear a "click," indicating that they are securely connected.

Continue Installation: Continue installing the remaining planks in the same manner, ensuring that their click-lock mechanisms are securely connected. Where necessary, use a saw or cutting tool to trim the planks to fit the room's edges and corners.

Step 4: Finish the Installation

Install the Final Row: As you approach the room's edges, you may need to measure and trim the final row of planks to ensure a proper fit. Use a cutting tool to carefully trim the planks.

Install Baseboards and Transition Strips: After installing the flooring, install baseboards and transition strips to cover the edges of the flooring and transition areas. These trim pieces protect the edges of the flooring and provide a more finished look.

Clean and Maintain: The final step is to clean the installation area and maintain your SPC flooring according to the manufacturer's recommendations. This includes regular sweeping, mopping, and preventing liquid accumulation.

The installation process for SPC vinyl flooring is relatively straightforward but requires careful planning and execution. If you lack experience in installing flooring, it's advisable to hire a professional to ensure the best results. Once the installation is complete, you'll enjoy a visually appealing, durable, and easy-to-maintain flooring that adds value and comfort to your home or commercial space.

SPC Flooring Maintenance Guide: Keeping Beauty and Durability

SPC flooring (Stone Plastic Composite flooring) is highly popular for its durability, aesthetics, and ease of maintenance. To ensure your SPC flooring remains in top condition over the long term, it's essential to take appropriate maintenance measures. In this article, we will provide a detailed explanation of how to effectively maintain your SPC flooring.

Step One: Daily Cleaning

Daily cleaning is the first and foremost task in maintaining SPC flooring. You can use a soft-bristle brush, mop, or vacuum cleaner to regularly clean the floor and remove dust, debris, and dirt. Here are some recommendations:

Use a soft-bristle brush or a vacuum cleaner: These can be used daily or weekly to keep the floor clean.

Damp mop: Periodically use a damp mop to wipe the floor and remove stains and dirt. Ensure that the mop is not overly wet to prevent moisture from seeping into the floor gaps.

Avoid using corrosive cleaners, strong acids, or strong alkalis to prevent damage to the floor surface.

Step Two: Deep Cleaning

In addition to daily cleaning, occasional deep cleaning is necessary. Here are some suggestions:

Cleaning agent selection: Use a mild cleaning agent specifically designed for SPC flooring. Dilute the cleaning agent with water according to the manufacturer's recommendations.

Avoid excessive moisture: During cleaning, avoid leaving excess water on the floor. After using a damp mop, quickly dry the floor with a clean towel.

Removing stubborn stains: For stubborn stains, you can use an appropriate cleaning agent, but avoid using overly abrasive substances.

Step Three: Protective Measures

To prolong the lifespan of your SPC flooring, you can take the following protective measures:

Use furniture pads: Place soft furniture pads under the legs of your furniture to prevent scratches and wear on the floor surface.

Avoid sharp objects: Prevent dragging sharp or heavy objects across the floor to avoid scratching or damaging the floor surface.

Use entrance mats: Place entrance mats at doorways to reduce the entry of dust and minimize wear.

Step Four: Regular Inspection

Regularly inspect the condition of your SPC flooring. Check for any damage, wear, or defects and take timely measures to address any issues to prevent worsening.

Step Five: Follow Manufacturer's Recommendations

Last but equally important, follow the recommendations and maintenance guidelines provided by the manufacturer. Different brands and models of SPC flooring may have different characteristics and requirements, so make sure to follow specific recommendations for maintaining your flooring.

By adhering to these maintenance guidelines, you can ensure that your SPC flooring maintains its beauty and durability, providing you with a long-lasting flooring solution for your home or commercial space. Proper maintenance will extend the lifespan of your floor, allowing you to enjoy the benefits of high-quality flooring for many years.

Work With Us

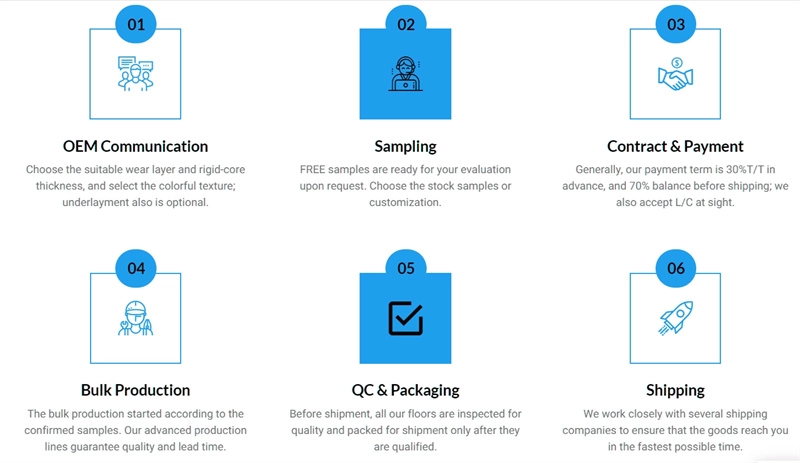

Our Working Proccess

305.webp)